Change brush cassettes, RSC

Comments

The warranty of the brush shaft is valid only when the original brush cassettes (from Øveraasen AS) are used.

It is possible to use steel brush, poly brush or a mix of both. The procedure below applies independent of brush material.

- Start the engine.

- Open the engine cover.

- Turn the brush to get good access on both sides. Use the control unit with the brush in manual mode or use the directional valves manually.

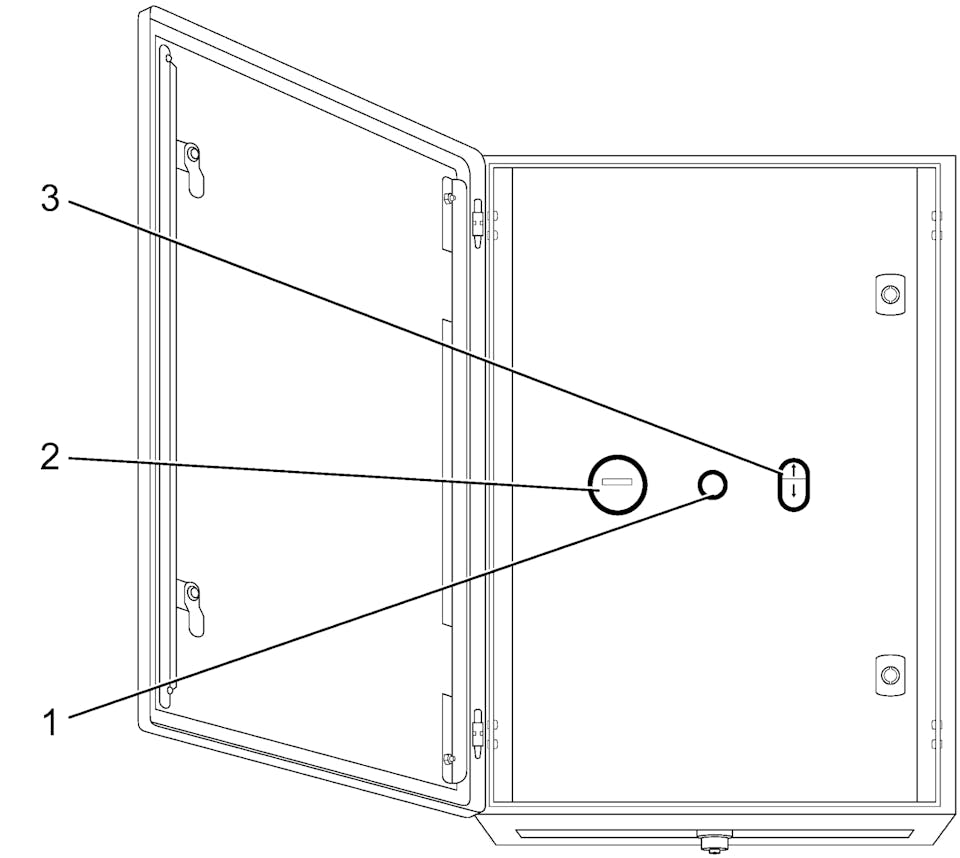

- Press and hold the button (1) for brush change procedure.

- Push button, brush change procedure

- Hour counter

- Raise/lower switch

Figure - Rear control panel

- Release the button when the brush is in the top end position.

- Stop the engine.

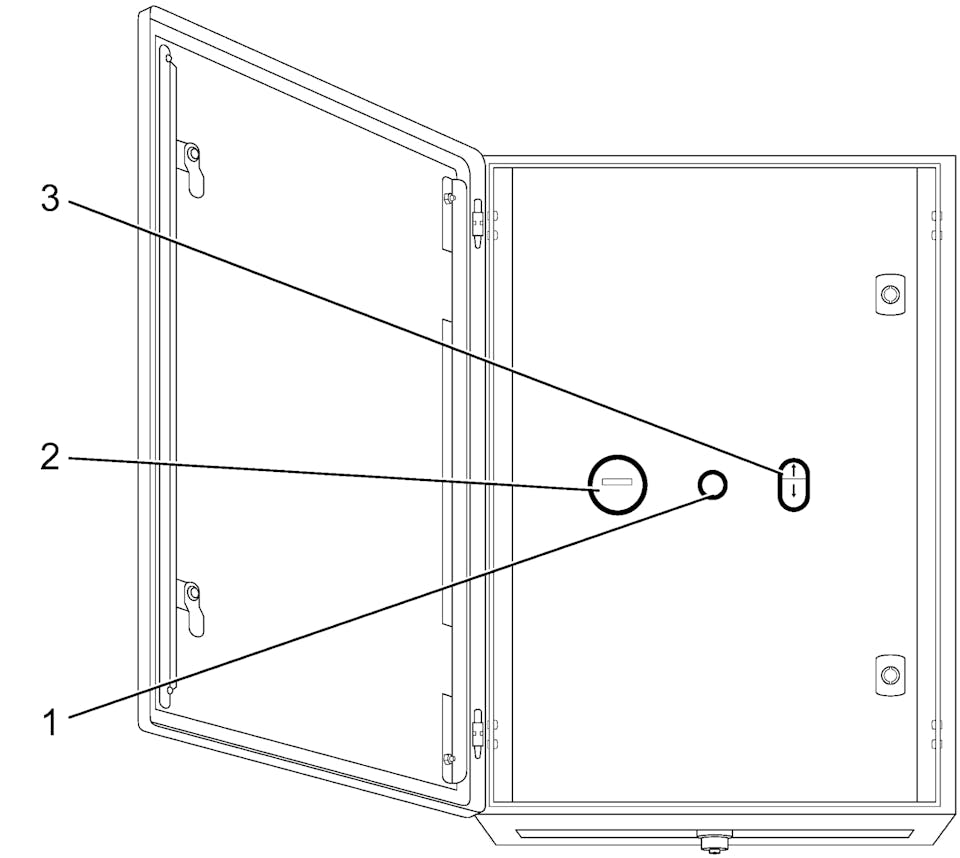

- Remove the screws holding the brush carrier plate on the left side of the brush.

Figure - Remove the brush carrier plate

- Remove the brush cassettes. If any brush cassettes are stuck use a wooden broomstick to push out the cassettes.

- Wash the shaft with water and a high-pressure washer. Rotate slowly, or alternatively tip the shaft to one side so that the water can run out.

- Check the aluminium profiles. These must not be so damaged that they make it difficult to replace the brush cassettes.

- Check that the plastic guides are not damaged or worn.

- Tighten the screws in the brush shaft during the first brush replacement. Tightening torque 50 Nm.

- Install new brush cassettes. If the brush cassettes do not enter the slots smoothly, lubricate with silicone. There might be an axial clearance when all brush cassettes are installed.

NOTE!

The brush carriers and the slots for the brush cassettes must gnot be lubricated with grease. Lubrication must only be performed with silicone-based lubricants.

- Install the brush carrier ring in position and tighten the screws to 50 Nm.

- Start the engine.

- Start the automatic brush calibration see

Comments

Let the brush spin for 5-8 minutes above ground level before

taking the brush into operation. This is in order to remove possibly

loosed treads.